Importance of Expert HVAC Installation and Assembly

When it comes to heating, ventilation, and air conditioning (HVAC) systems, the precision of installation and assembly is just as crucial as the quality of the system itself. Expert HVAC installation ensures that your system operates efficiently, safely, and reliably over its lifespan. However, every home or building presents unique challenges that may require custom tool solutions.

Custom Tool Solutions for HVAC Challenges

In the world of HVAC installation, one size does not fit all. Unique structural designs, space limitations, and specific system requirements often demand tailored solutions to execute a successful installation. Custom tool solutions help technicians navigate these challenges effectively, ensuring a flawless fit and optimal performance.

Facing Unique Installation Challenges

- Space Constraints: In buildings with limited space, custom-made slimline tools can assist in maneuvering through tight areas.

- Unusual Architecture: Historic or architecturally complex buildings might require specially designed tools to accommodate their peculiar structures.

- Custom HVAC Designs: Some advanced HVAC systems have proprietary components that need specialized tools for proper installation.

Benefits of Customized Tools for HVAC

- Enhanced Precision: Tailored tools allow for precise adjustments and fittings, which is essential for the optimal function of an HVAC system.

- Increased Efficiency: With the right tools designed for specific tasks, technicians can complete the installation faster and more efficiently.

- Improved Safety: Using the appropriate tools minimizes the risk of injury to technicians and damage to the component or system being installed.

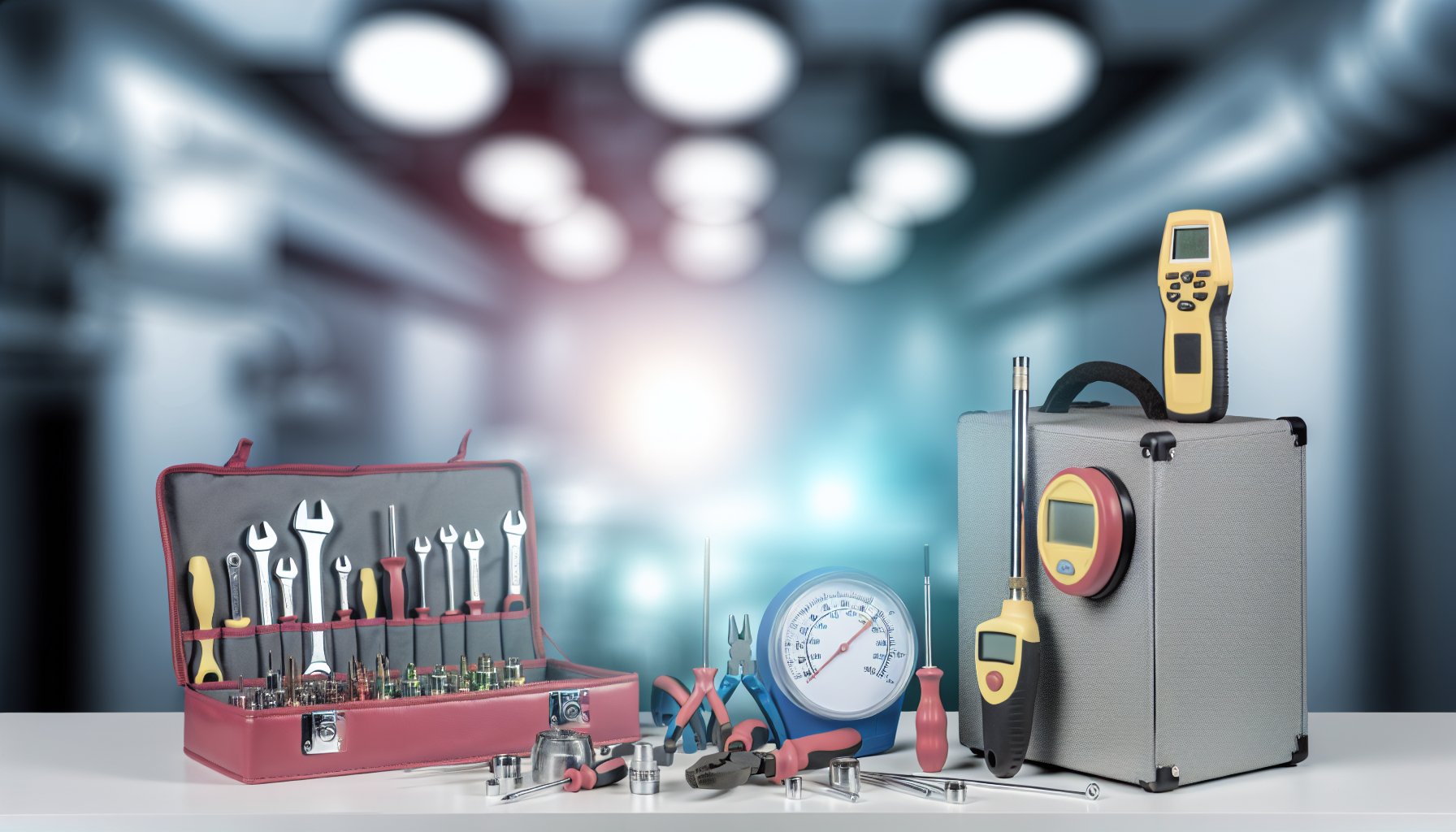

Custom Tool Solutions in Practice

Custom tool solutions in HVAC installations are not just theoretical. Many successful installations have benefited from the implementation of bespoke tools. These tools are often developed in collaboration with HVAC engineers, technicians, and tool manufacturers to address the unique demands of each project.

Case Studies of Successful Custom Tool Implementations

- In a residential project with low ceiling clearance, a custom extendable wrench was crafted, allowing technicians to secure ductwork without causing damage to surrounding structures.

- For a commercial HVAC system with hard-to-reach valves, a set of custom angled ratchet adapters was developed, making it possible to tighten connections without dismantling nearby components.

- In an HVAC upgrade for a historic building, traditional tools were ineffective due to the uniqueness of the aged structure. Customized, gentle fastening tools were created to preserve the integrity of the original framework.

Choosing the Right HVAC Expert for Custom Solutions

Selecting an HVAC professional with experience in custom tool creation is crucial. This ensures your installer is prepared to deal with unforeseen issues that may arise during the process. Look for a provider with a track record of innovation and problem-solving skills, as well as one who understands the importance of maintaining the HVAC system’s warranty and specifications.

What to Look for in an Expert

- Experience: Search for a service provider with a proven history of dealing with complex HVAC installations.

- Problem-Solving Skills: Ensure they have the ability to quickly adapt and create solutions for unpredictable challenges.

- Inventiveness: A good HVAC technician should be able to think outside the box and collaborate on the development of new custom tools.

- Reputation: Look for positive customer testimonials and case studies that demonstrate the company’s efficacy in providing custom tool solutions.

Maintaining Quality and Compliance

It’s important to remember that any tool used in HVAC installation must still comply with industry standards and regulations. Custom tools should be constructed with quality materials and should be tested for safety and efficacy. Working with certified experts ensures that even with the use of custom tools, your HVAC system remains up to code and functions as intended.

Ensuring Compliance

- Only collaborate with certified HVAC technicians who understand local codes and regulations.

- Custom tools should be produced with quality materials to prevent premature failure and possible safety hazards.

- Properly documenting the use of custom tools and their impact on the installation process can be beneficial for future maintenance and warranty claims.

FAQ Section

Here’s a list of frequently asked questions to help guide you through the intricacies of custom tool solutions in HVAC installation.

Why are custom tools necessary for some HVAC installations?

They are required when standard tools cannot accommodate unique building structures, tight spaces, or specific system designs that necessitate unconventional approaches to installation.

Can custom tools void my HVAC system’s warranty?

Not if they are used correctly. It is essential to work with certified HVAC technicians who utilize custom tools that won’t compromise the integrity of your system or its warranty.

Are custom tools safe to use?

Yes, as long as they are designed and constructed according to industry standards and tested thoroughly before use.

How do I find an HVAC service provider who can create custom tool solutions?

Look for technicians with experience, a strong problem-solving portfolio, and positive customer reviews. Make sure they have a history of working with unique installation challenges and implementing custom solutions.

Will the use of custom tools increase the cost of HVAC installation?

The development of custom tools may require additional investment, but it can result in savings over time due to increased efficiency, fewer repairs, and prolonged system life.