Introduction to HVAC Tools for Tight Spaces

When you’re working on HVAC systems, space is often at a premium. Tight spots are not just difficult to navigate, but they also require specialized tools that can do the job without causing damage to the equipment or the technician. In this guide, we will delve into the ultimate HVAC tools needed for installations and assemblies in confined spaces.

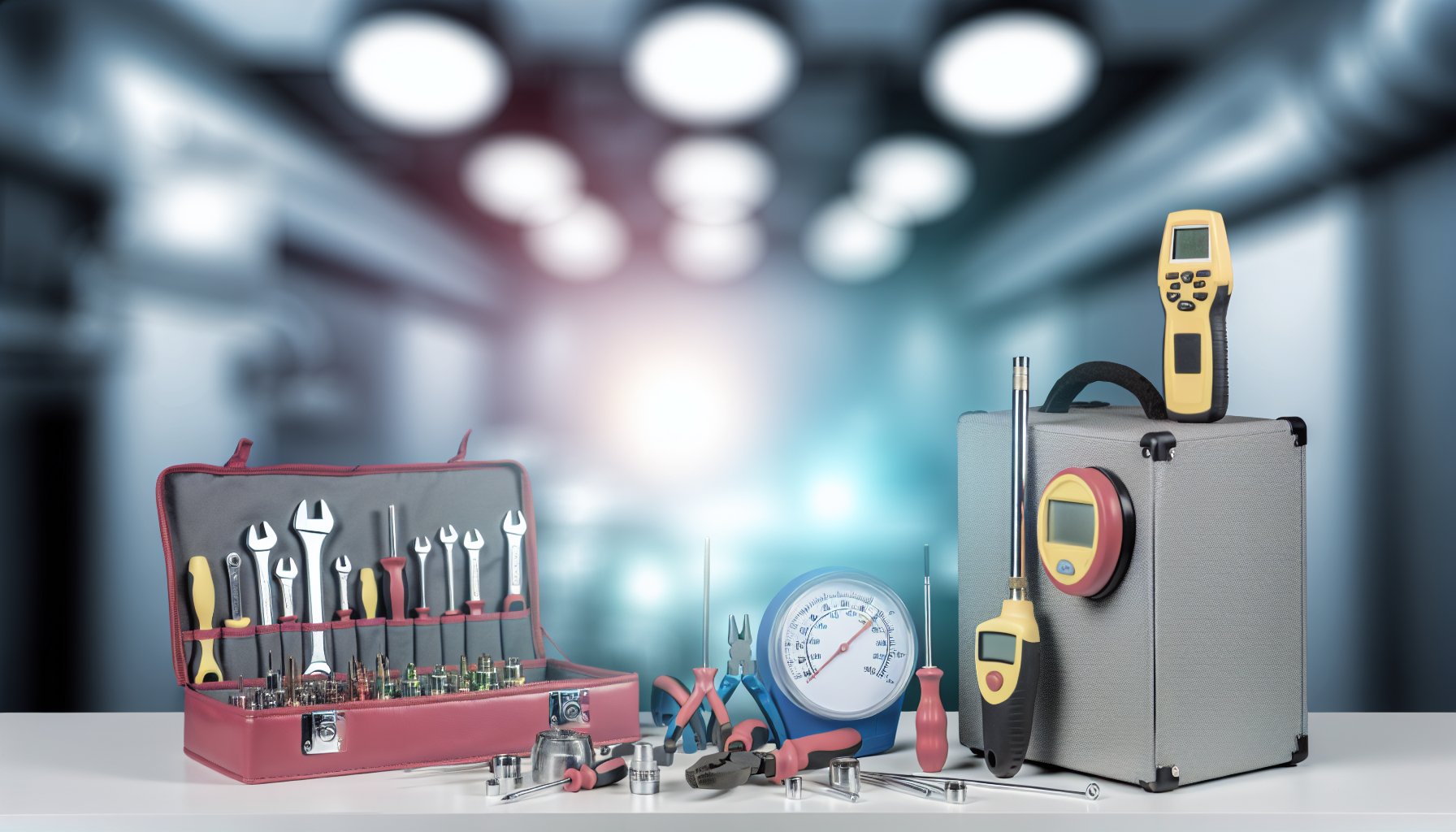

Essential HVAC Tools for Small Spaces

You’ll need a variety of precise and compact tools to ensure you can handle any job with confidence. Here’s a meticulously compiled list that addresses your need for efficiency and convenience.

Screwdrivers and Nut Drivers

- Slim Screwdrivers: Opt for models that are designed for electrical work, as they often have a thinner profile that’s perfect for reaching into tight spaces.

- Ratcheting Nut Drivers: Ratcheting nut drivers save on space and time by allowing continuous work without the need to lift the tool off the fastener.

Wrenches

- Adjustable Wrenches: They’re invaluable when you need versatility without carrying an entire set of fixed-size wrenches.

- Basin Wrench: This is an essential tool for reaching faucet nuts that are usually in a tight space behind the sink.

Pliers

- Needle Nose Pliers: Their long, slender design makes them perfect for grabbing wires or fasteners in awkward places.

- Slip-Joint Pliers: The adjustable jaws allow for the gripping of various sized objects, especially in restricted areas.

Specialized Tools

- Inspection Mirrors: For visual access to areas that are impossible to reach or see directly.

- Flexible Magnetic Pick-Up Tool: It can reach into tight spots to retrieve small metal items easily.

Techniques for Working in Confined Spaces

Having the right tools is only part of the solution; knowing how to use them effectively in small spaces is equally important.

Organization and Planning

- Before starting, plan your steps carefully. Visualize the assembly or installation process.

- Organize your tools neatly so you can reach for what you need without fumbling or losing precious space.

Flexibility and Adaptation

- Be ready to adapt on the fly. If a tool isn’t working as intended, don’t force it. Try a different angle or tool.

- Use your tools’ flexibility features. Extendable handles and flexible shafts can be a real asset.

Patience and Precision

- Work slowly and deliberately. Tight spaces do not lend themselves to rushing.

- Use precision to avoid stripping screws or damaging components.

Maintenance of Tools

Maintaining your HVAC tools is crucial for their longevity and effectiveness, especially those designed for tight space usage.

Cleaning and Lubrication

- After each use, clean your tools to remove any dirt or grease that could cause damage over time.

- Lubricate moving parts lightly to ensure smooth operation and prevent rust.

Inspection and Repair

- Inspect your tools regularly for signs of wear and tear. Early detection of faults can save you from on-the-job breakdowns.

- Have a professional repair or sharpen tools that are not functioning at their best.

Proper Storage

- Store each tool in its designated place, ideally in a climate-controlled environment to prevent moisture damage.

- Use tool organizers designed for compact storage, ensuring each tool is secure and accessible.

Advanced Tools for Experienced Technicians

If you are a seasoned HVAC technician, you may want to invest in advanced tools that can provide an extra edge in tight space situations.

Digital Tools

- Borescopes: These digital viewing tools can access and transmit images from within tight spots to your smartphone or screen.

Power Tools

- Compact Power Drivers: These are designed to fit in smaller spaces and can drastically reduce installation or disassembly time.

Adaptation Kits

- Right-Angle Adapters: Useful for drills and drivers, these adapters allow you to work perpendicular to the tool’s usual orientation, which is ideal for tight corners.

FAQs

What’s the most versatile tool for tight space HVAC work?

The most versatile tool could be a high-quality, adjustable wrench or a set of compact, ratcheting nut drivers. These tools can adjust to different sizes and situations, making them invaluable in restrictive spaces.

How can I ensure I don’t damage components in tight spaces?

Using the right size and type of tool is critical to prevent damage. Also, applying the proper amount of pressure and not forcing tools into spaces they don’t fit are key practices.

Are power tools safe to use in tight HVAC spaces?

Yes, with the right attachments like right-angle adapters and when used with caution, power tools can be a great asset in tight spots. Always make sure there is enough clearance for the tool to operate safely.

How often should I be maintaining my tools?

Tools should be cleaned after every job, and an inspection for any loose parts or signs of wear should be conducted periodically. Aim for more thorough maintenance checks every few months, depending on usage frequency.

Can magnetized tools help in tight spaces?

Yes, magnetized tools can hold onto screws and bolts, reducing the chance of dropping them in hard-to-reach areas. They can greatly improve efficiency in tight space operations.