Introduction to HVAC Mastery

Heating, Ventilation, and Air Conditioning (HVAC) systems are crucial for maintaining comfortable indoor environments. Technicians in this field need to be well-equipped with knowledge and the right tools to perform their jobs efficiently. Understanding the essential tools and measurement techniques is imperative to avoid common errors that can lead to system malfunctions, unsatisfied customers, and costly repairs. In this guide, we’ll explore the tools and techniques that are the backbone of HVAC mastery.

Essential HVAC Tools

To ensure precise measurements and high-quality work, every HVAC professional should have a set of essential tools. Here is a list of must-have instruments:

- Multimeters: These are invaluable for diagnosing electrical issues. They measure voltage, current, and resistance, which are critical for troubleshooting HVAC systems.

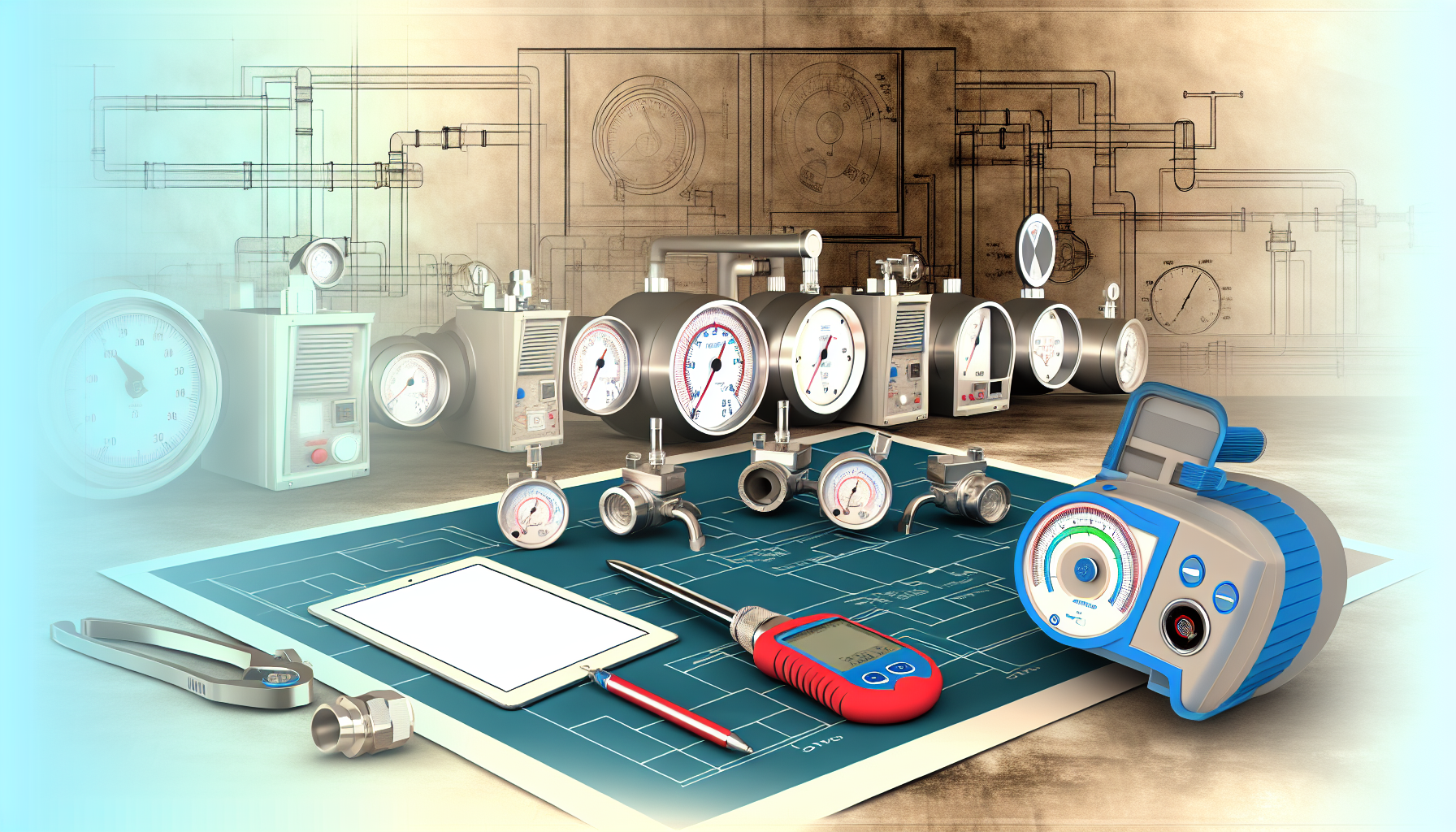

- Manifold Gauge Set: Used to check pressure within air conditioning units and refrigerators to ensure they are operating correctly.

- Leak Detector: An essential tool for identifying refrigerant leaks within the system.

- Thermometer: Accurate temperature readings are critical for HVAC work, whether you’re assessing ambient air temperature or the temperature of specific components.

- Vacuum Pump: After repairs, a vacuum pump is pivotal for removing contaminants and moisture from the system before recharging it with refrigerant.

- HVAC Software: This includes diagnostic programs and apps that can assist with calculations and service reports.

- Crimpers and Shears: For cutting and shaping sheet metal used in ductwork.

- Tubing Cutter: This helps in making clean cuts in the tubing to prevent leaks and ensure a proper fit.

- Psychrometer: Essential for measuring relative humidity and verifying the performance of the HVAC system.

HVAC Measurement Techniques

Proper measurements are the key to successful HVAC maintenance and repair. Here are essential measurement techniques you should master:

- Temperature Measurements: Understanding how to use thermometers to measure different parts of the HVAC system is crucial. Always penetrate air ducts for a more accurate representation of the air temperature within.

- Pressure Measurements: Utilize manifold gauges to read suction and discharge pressures in the system. Comparative analysis with manufacturer specifications is essential to determine if the system is functioning correctly.

- Electrical Measurements: With a multimeter, you can measure voltage drops, resistances, and diagnose potential electrical failures. Familiarize yourself with the electrical schematics of the systems you work with.

- Refrigerant Charge: Using the proper tools to measure the refrigerant lines and accurately calculating the charge can prevent system inefficiencies or failures.

Avoiding Common Errors

Common errors can be minimized or avoided with a disciplined approach to using tools and techniques accurately:

- Proper Tool Maintenance: Regularly serviced and calibrated tools ensure that you’re working with instruments that provide accurate measurements.

- Adhering to Specifications: Always refer to the manufacturer’s specifications for pressure, temperature, and electrical settings. Deviations from these could result in misdiagnosing problems.

- Thorough System Inspection: Never rush through a job. Take the time to thoroughly inspect the entire system before pinpointing the problem.

- Continuous Learning: HVAC technology is constantly evolving, so stay current with new tools and measurement techniques in the industry.

FAQ Section

Here are answers to some frequently asked questions about mastering HVAC tools and measurement techniques:

Q: Which is the most important HVAC tool to master first?

A: It’s crucial to master the use of a multimeter as it is one of the most versatile tools in the HVAC industry. It can help diagnose a plethora of electrical issues that are common in HVAC systems.

Q: How often should I calibrate my measurement tools?

A: Measurement tools should be calibrated at least once a year or according to the manufacturer’s recommendations. However, if a tool has been dropped or damaged, it should be calibrated before its next use to ensure accuracy.

Q: Are digital tools always better than analog ones?

A: Digital tools usually offer more precision and are easier to read than analog tools. However, the best tool is one that you are comfortable using, provides accurate measurements, and meets the needs of the job.

Q: How do I ensure that I’m taking accurate pressure measurements with my manifold gauge set?

A: To ensure accuracy with your manifold gauge set, you should first zero out the gauges before use, ensure your hoses and connectors are tight and leak-free, and always make sure the system is at a stable operating condition before reading pressures.

Q: What’s the best way to stay updated on new HVAC tools and measurement techniques?

A: Attend industry workshops, training sessions, and conferences. Subscribing to industry magazines, online forums, and participating in professional social media groups are also great ways to stay informed.

Mastery of HVAC tools and accurate measurement techniques can dramatically improve job performance and customer satisfaction. As you gear up with the essential tools and refine your measurement skills, remember that avoiding common errors is just as important. With a proactive approach to tool maintenance, continuous learning, and adherence to proper measurement practices, you can become an expert technician that clients trust. Keep these tips in mind, practice diligently, and HVAC mastery will be within your reach.