Understanding Ultrasonic Leak Detection in HVAC Maintenance

Maintaining an efficient and well-functioning HVAC system is critical to both comfort and cost savings in residential and commercial buildings. One of the challenges that HVAC technicians face is locating leaks, which can significantly impact system performance. Traditional methods of leak detection often involve time-consuming and sometimes inaccurate procedures. However, with the advent of ultrasonic leak detection tools, HVAC professionals can now diagnose issues with greater precision and speed.

The Basics of Ultrasonic Leak Detection

In HVAC systems, gas or refrigerant leaks emit sound waves as the substance moves from high pressure to low pressure. These sound waves are at a frequency that is usually beyond human hearing. Ultrasonic leak detection devices are designed to pick up these high-frequency sounds and convert them into audible noises or visual indicators, allowing technicians to pinpoint the exact source of a leak.

Advantages of Using Ultrasonic Tools for HVAC Maintenance

- Precision: Ultrasonic detectors can locate leaks with a high degree of accuracy, reducing guesswork and unnecessary repairs.

- Speed: These tools quickly identify the leak source, allowing for prompt repairs that minimize system downtime.

- Convenience: Ultrasonic leak detection can be performed during regular system operation, eliminating the need for system shutdown.

- Cost Savings: By detecting leaks early and accurately, these tools help prevent larger, more expensive repairs and reduce refrigerant losses.

- Safety: Ultrasonic leak detection is non-intrusive and does not require any contact with the system, reducing the risk to technicians.

How to Master HVAC Maintenance with Ultrasonic Leak Detection

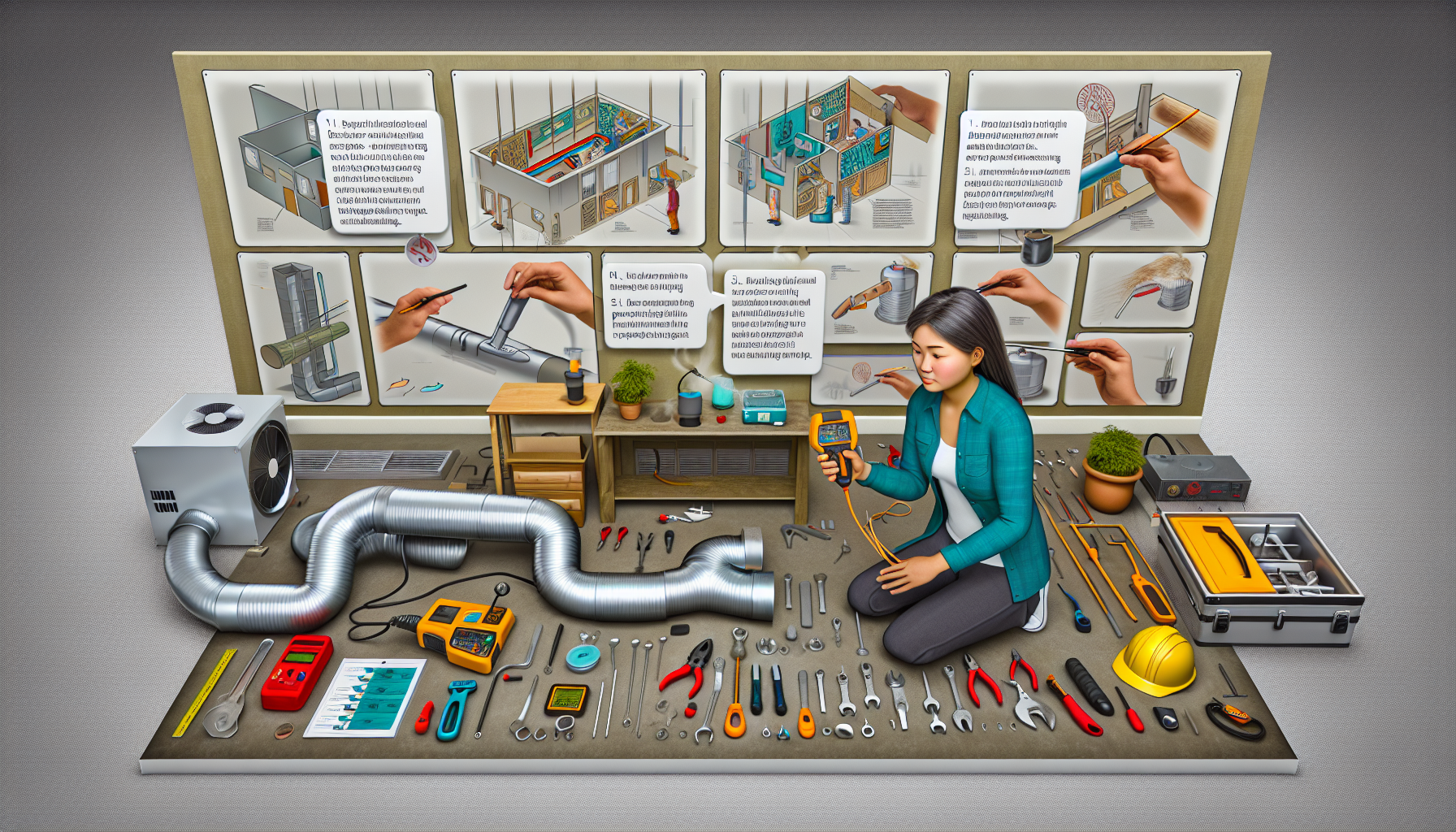

Step-by-Step Guide to Using Ultrasonic Leak Detection

- Understand Your Equipment: Familiarize yourself with the ultrasonic leak detector you are using. Read the manual to understand its functions, limitations, and proper usage.

- Perform a Visual Inspection: Before using the ultrasonic device, visually inspect the HVAC system for any signs of damage or wear that may indicate potential leak points.

- Set Up Your Equipment: Turn on the ultrasonic leak detector and adjust its settings according to the manufacturer’s recommendations for the type of HVAC system you are inspecting.

- Scan the System: Slowly move the ultrasonic detector along the HVAC components, paying close attention to common leak points such as valves, fittings, and connections. Listen for the audible tone or observe the visual indicators of leaks.

- Mark the Leak Points: When you identify a potential leak, use a marker to indicate the location. This will help you or a repair technician address the issues subsequently.

- Verify the Leaks: For confirmation, you may want to use a secondary method like a soap bubble solution to visually confirm that the leak detected by the ultrasonic tool is accurate.

- Record Your Findings: Keep thorough records of the leaks detected, including their locations and severity. This information is valuable for planning repairs and future maintenance.

- Proceed with Repairs: After the leaks have been identified and marked, it’s time to perform the necessary repairs. This may include tightening connections, replacing parts, or other actions based on the type and location of the leak.

- Final Testing: Once repairs are completed, use the ultrasonic detector again to ensure that all leaks have been effectively sealed.

Additional Tips for Efficient Ultrasonic Leak Detection

- Practice Regularly: Becoming proficient with ultrasonic leak detection takes regular practice. Familiarize yourself with the sounds and indicators associated with leaks of various sizes.

- Maintain Your Equipment: Regularly check the calibration of your ultrasonic device and replace parts like batteries and sensors according to the manufacturer’s guidelines to ensure accurate readings.

- Minimize Background Noise: While ultrasonic devices can function in noisy environments, eliminating background noise when possible will make it easier to hear the leak indicators.

- Invest in Quality Headphones: High-quality noise-cancelling headphones can enhance the detection capability of your ultrasonic tool, especially in loud settings.

FAQ Section

What is an ultrasonic leak detector?

An ultrasonic leak detector is a device that captures high-frequency sound waves emitted by gas or refrigerant escaping from an HVAC system and converts them into audible signals or visual cues to help locate leaks.

How accurate are ultrasonic leak detectors?

Ultrasonic leak detectors are highly accurate, especially for small leaks that other detection methods may overlook. Their sensitivity allows them to detect leaks that might not impact the system’s performance immediately but could lead to more significant issues over time.

Can ultrasonic detectors find leaks in any type of HVAC system?

Yes, ultrasonic detectors are versatile and can be used on various HVAC systems regardless of their size or type. They are particularly useful for detecting leaks in pressurized systems, including air conditioning and refrigeration units.

Is an ultrasonic leak detector easy to use?

While there is a learning curve to effectively use an ultrasonic leak detector, with training and regular use, HVAC technicians can quickly master the tool. The key is to become familiar with the device’s operation and the particular sounds associated with different leak types.

Do I need to shut down the HVAC system to use an ultrasonic leak detector?

No, one of the advantages of using an ultrasonic leak detector is that it can be used while the system is operating. This allows for real-time diagnostics and reduces maintenance downtime.